50%

Technical Specification

- It must dispense 300ml in under 5 seconds accurately and consistently to the nearest 5ml

- It must have a manual dispense mode or easy to access manual dosing

- It could include a jug rinser

- An array of containers must fit within a standard supermarket delivery cate (600 x 400 X 200mm)

- The milk must remain at 5C or below throughout the entire system for 2 hours

- The kegs should be an existing standard, for example from the beer industry to reduce start up and accessibility costs

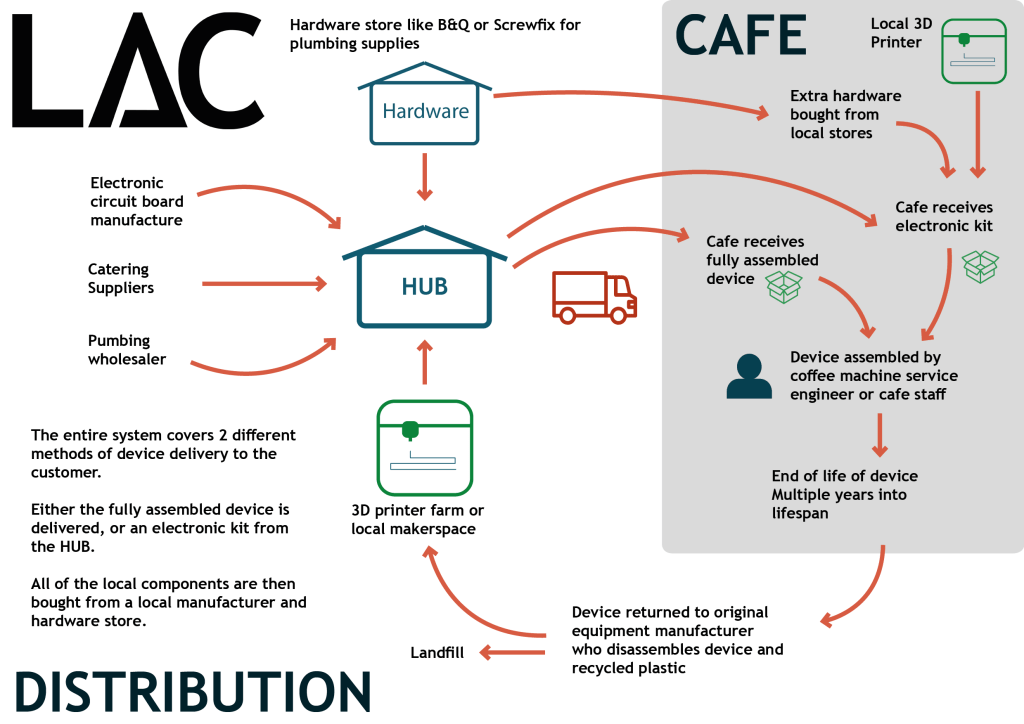

Distribution

This diagram shows what parts can be made locally, and what parts have to be bought in. The hub will sell electronic kits and fully assembled devices, which allows the device to be distributed across the country as digital files, reducing mileage of components.

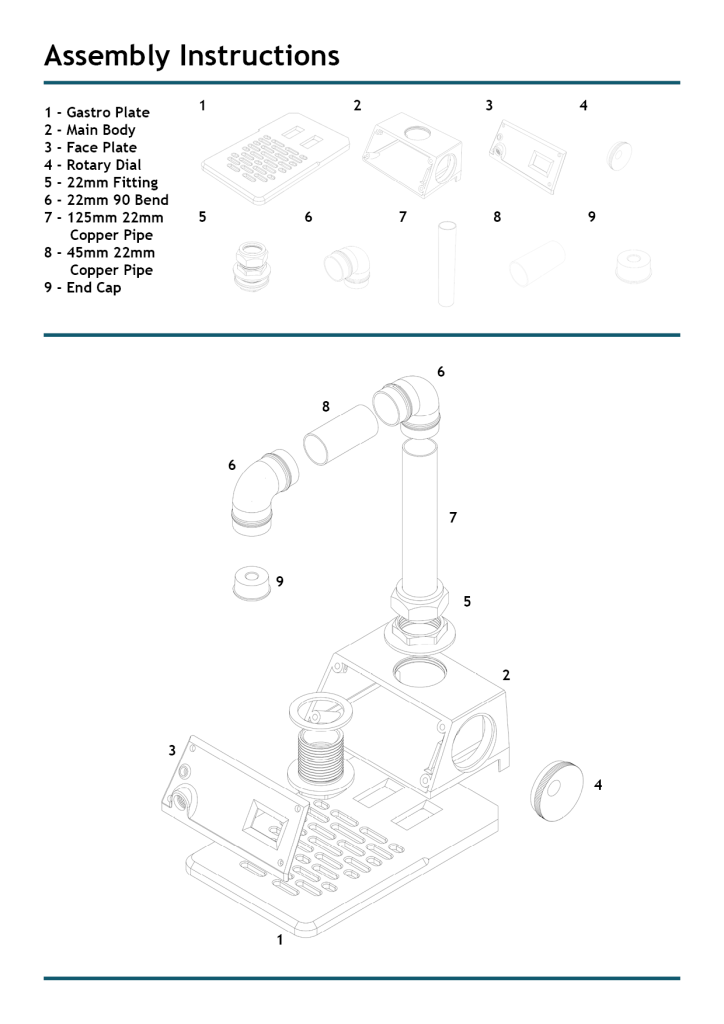

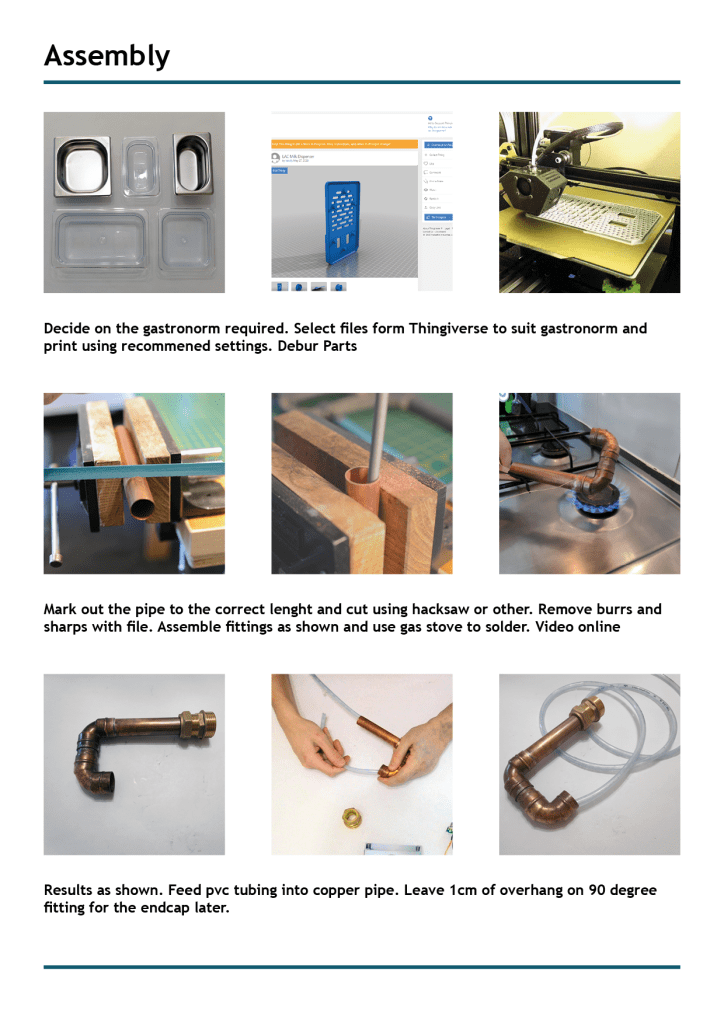

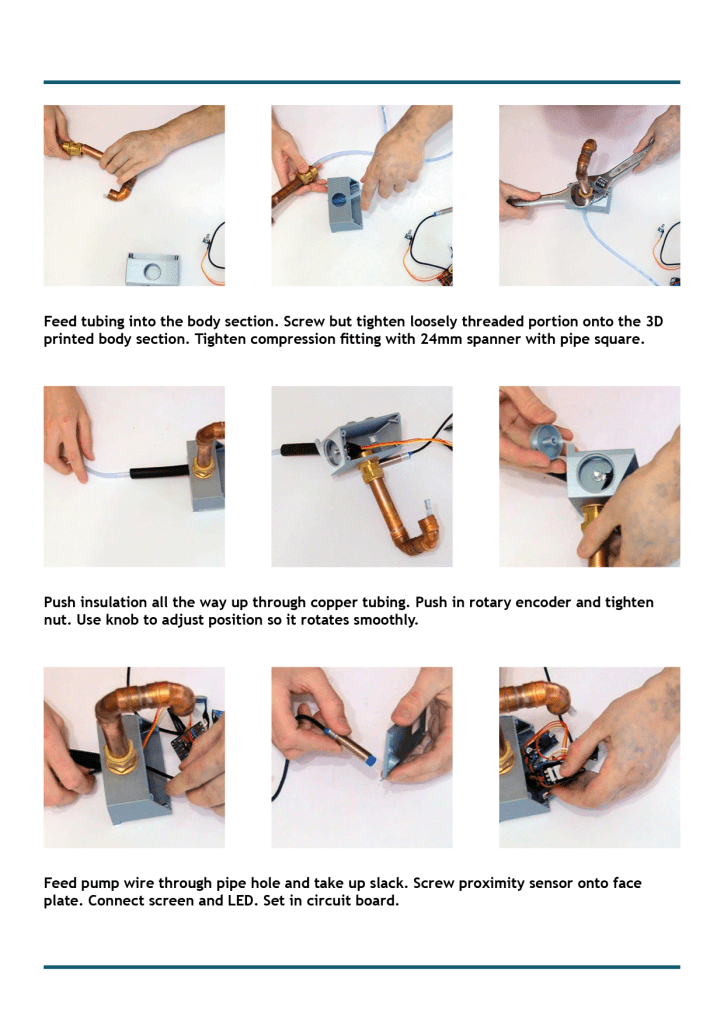

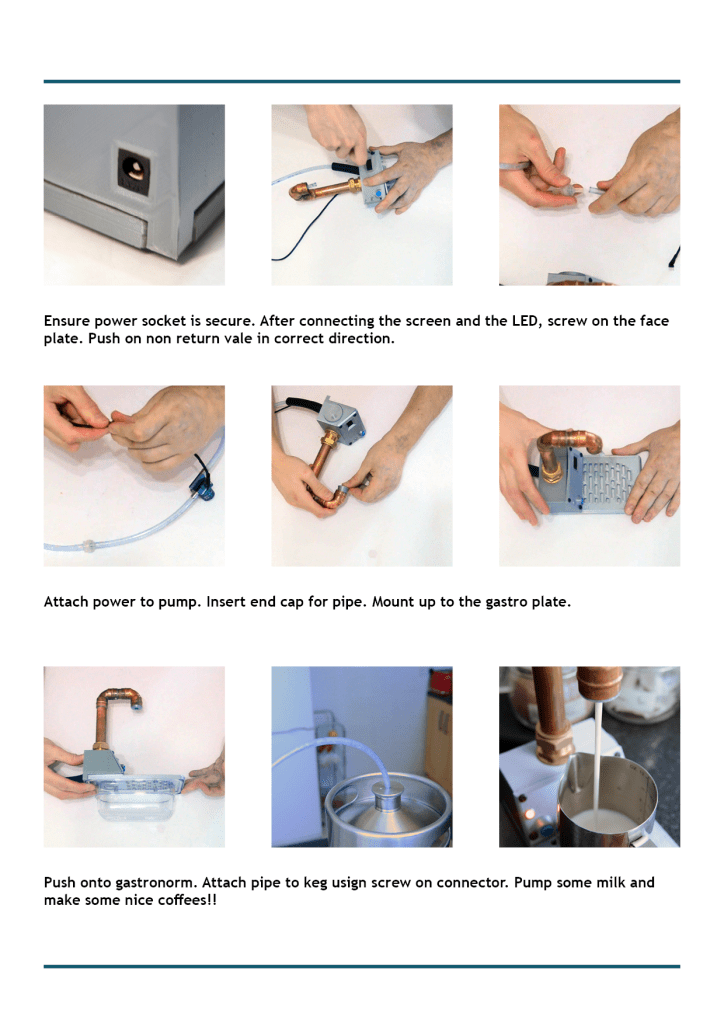

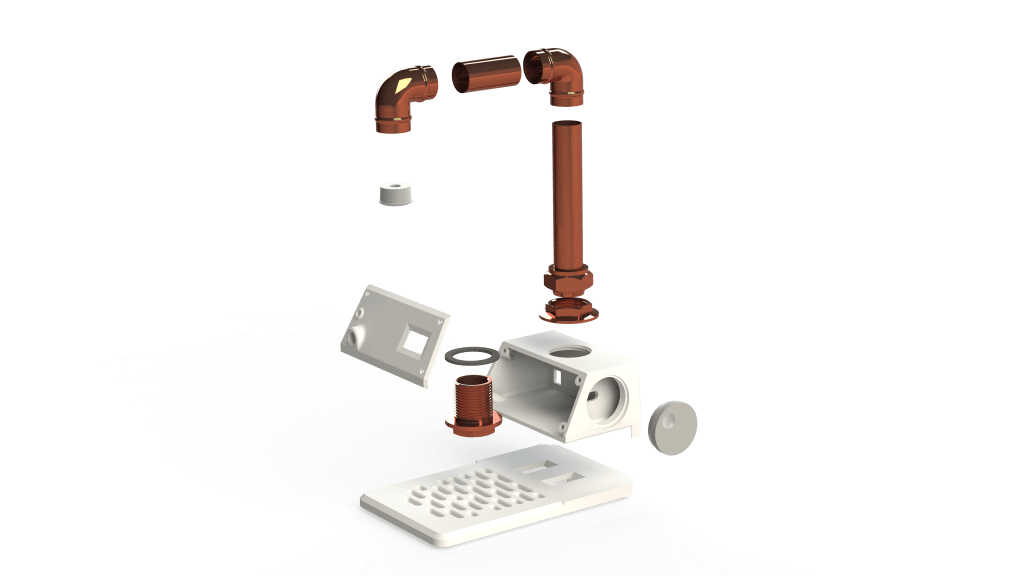

Assembly

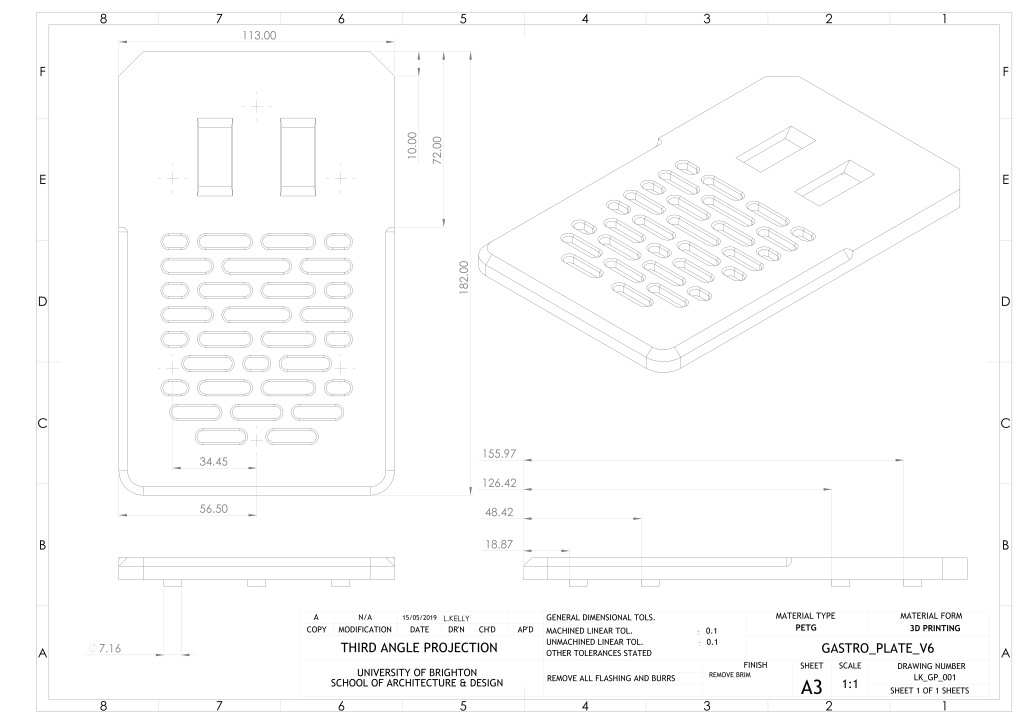

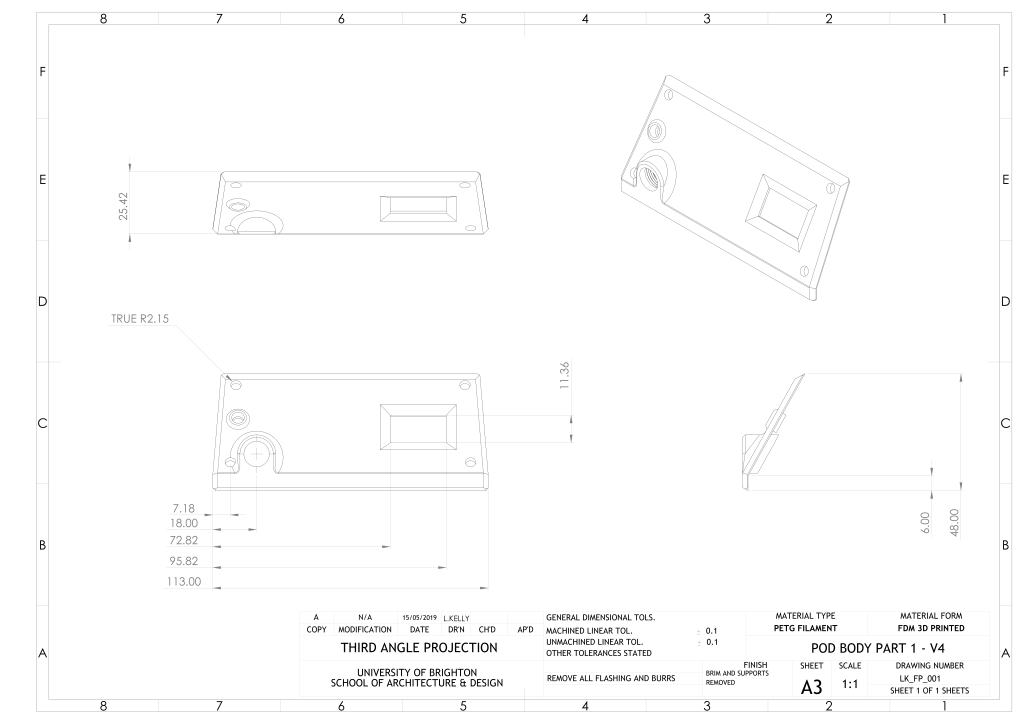

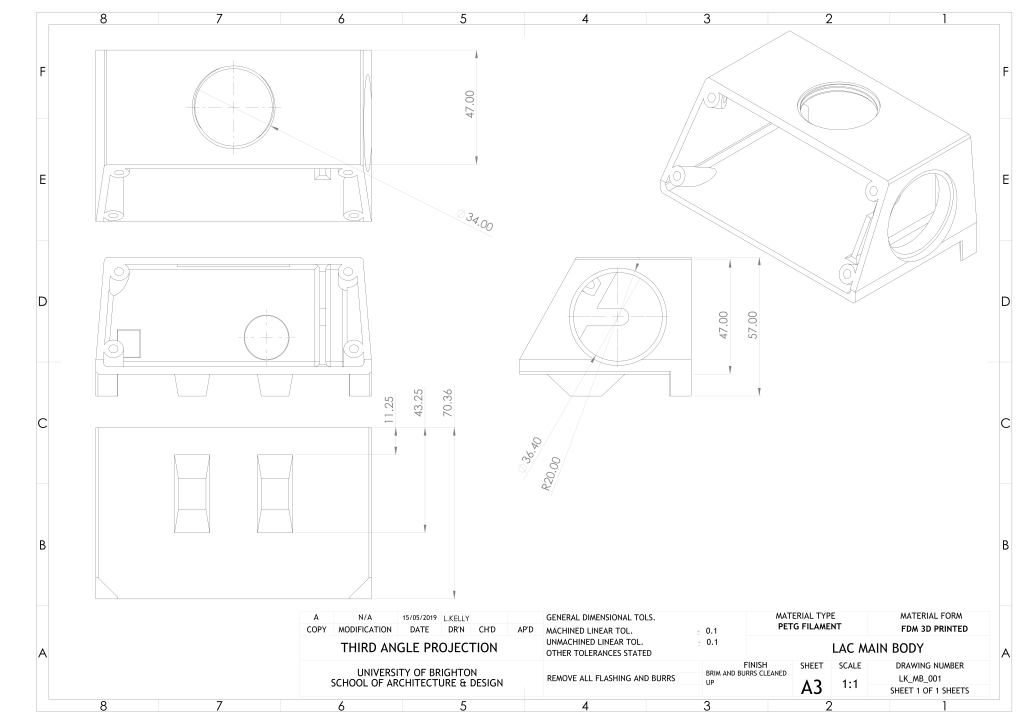

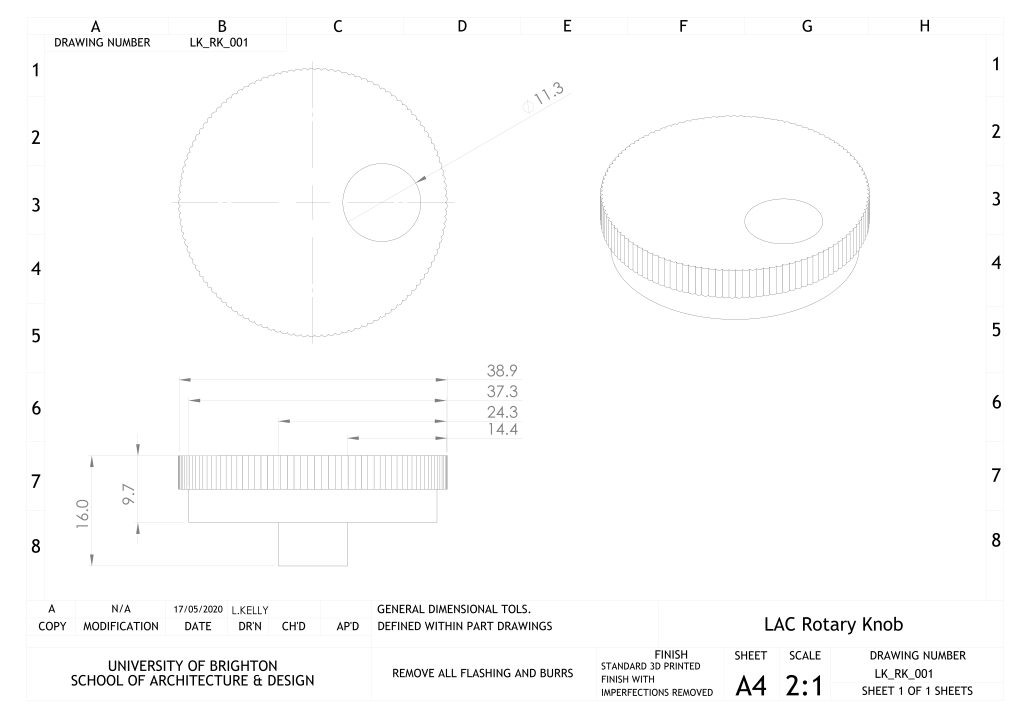

Manufacturing

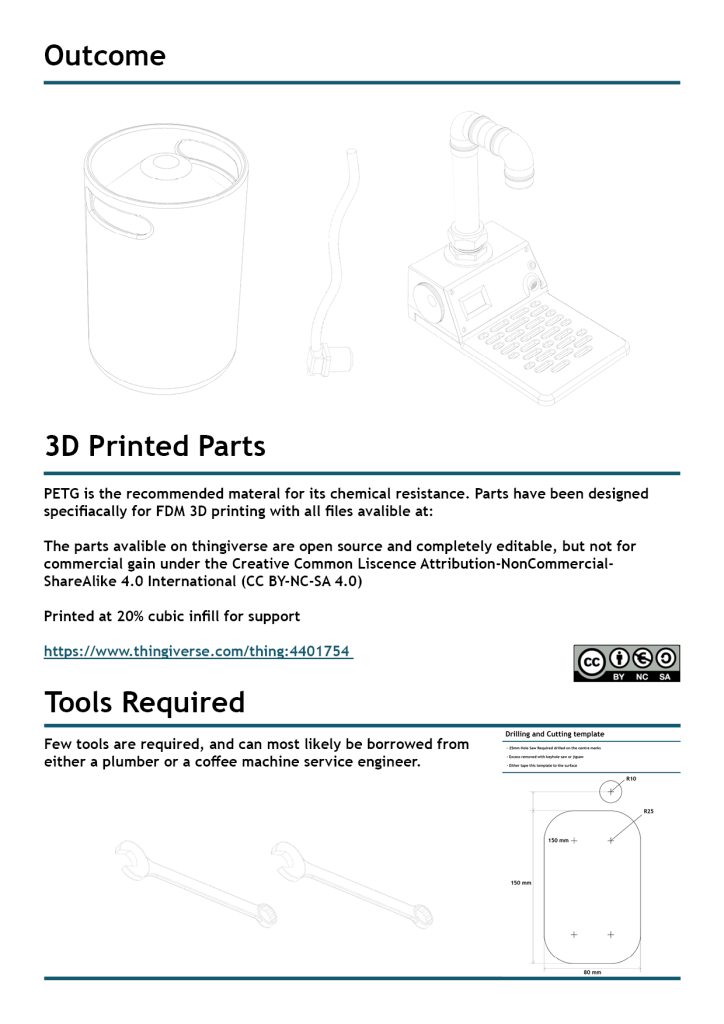

The main sections are 3D printed by the distribution as in the above diagram. The costs are shown in the BoM. This allows manufacture to be distributed and open source, reducing the environmental impact.

PETG

PETG is chosen over different materials, as it is easy to print with lower cost machines, has good resistance to chemicals so can be sanitised and is more resistant than PLA.

Pipe Soldering

The pipe fittings need to be solder and this can be done on a home or commercial stovetop.

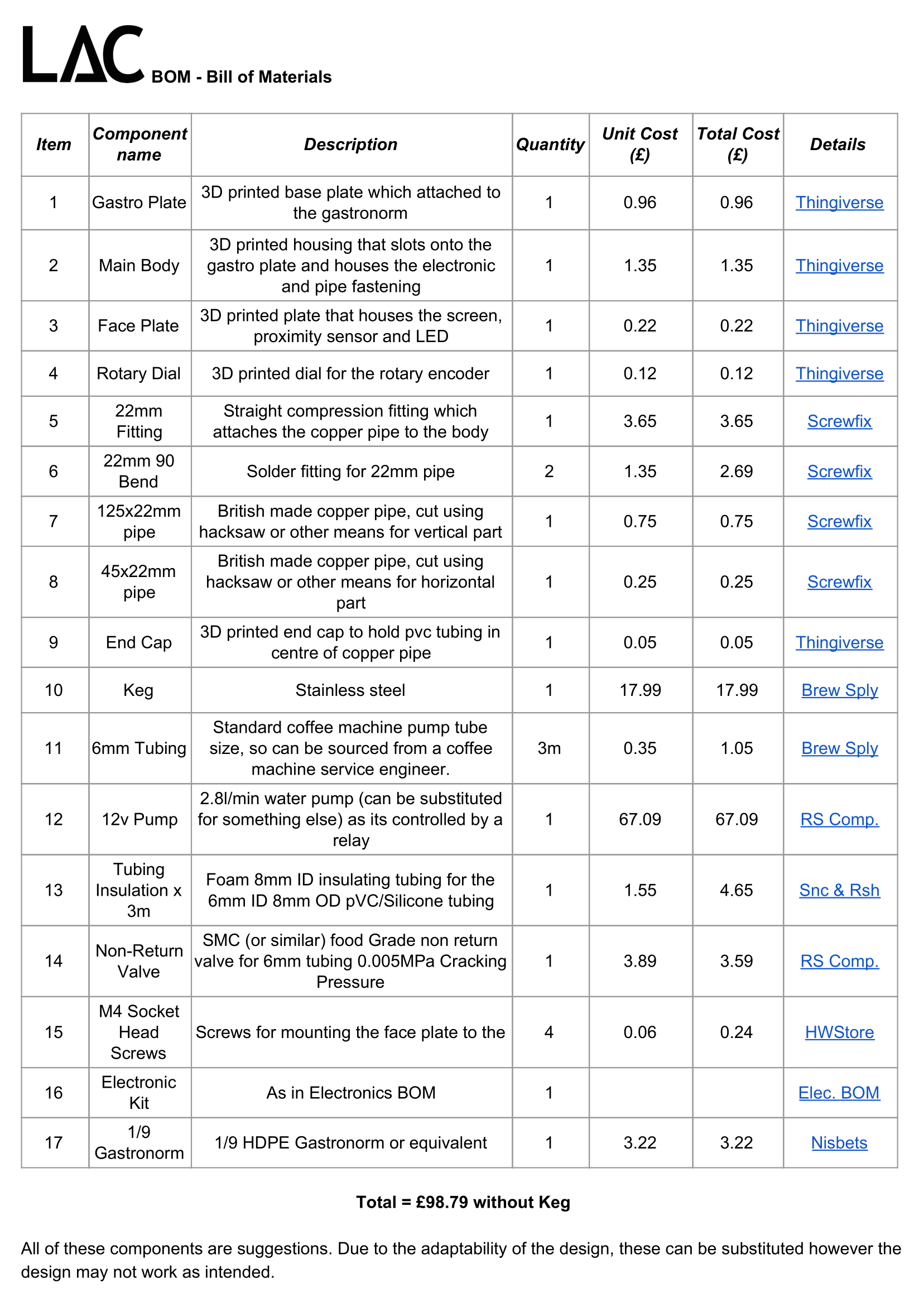

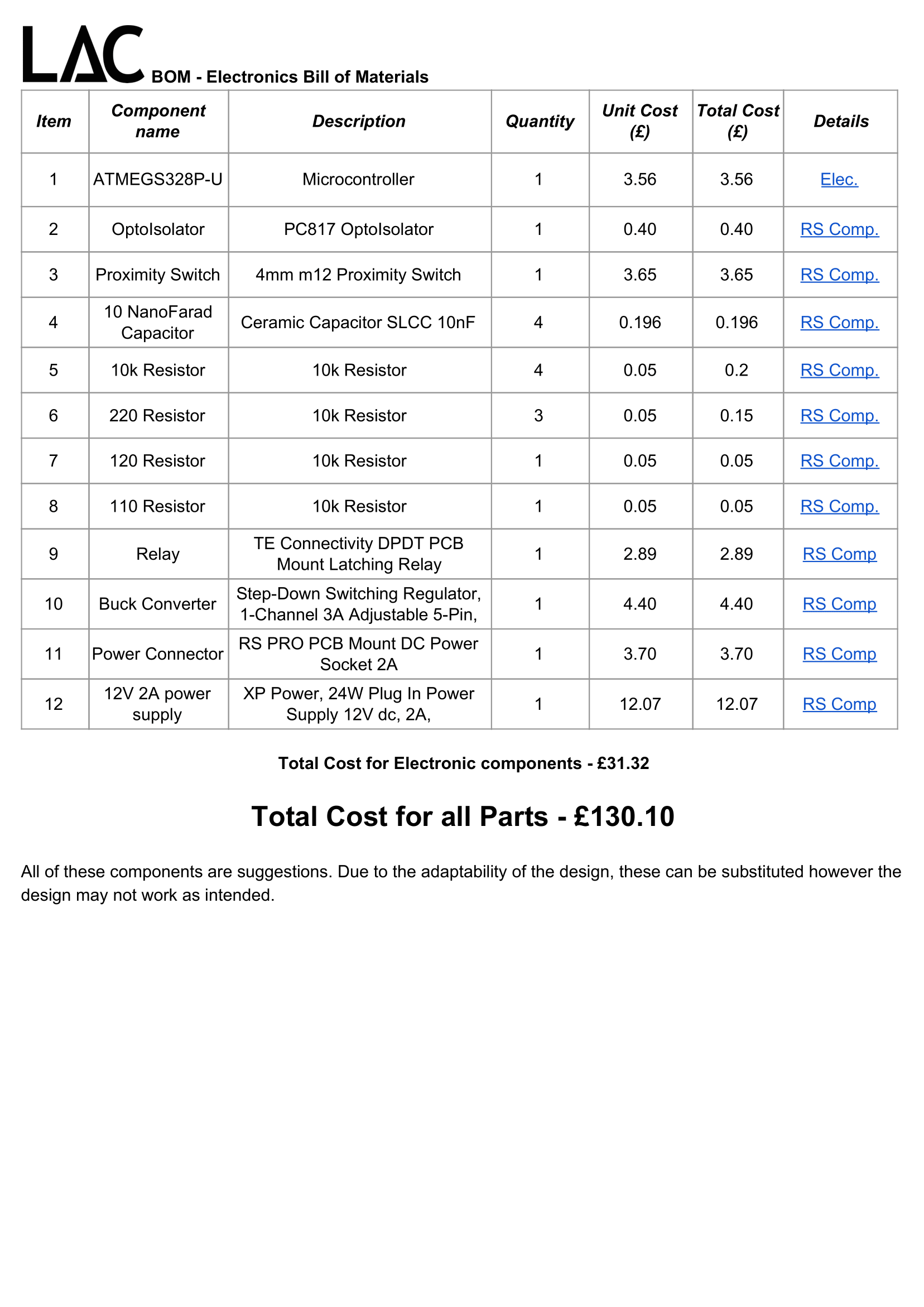

BoM

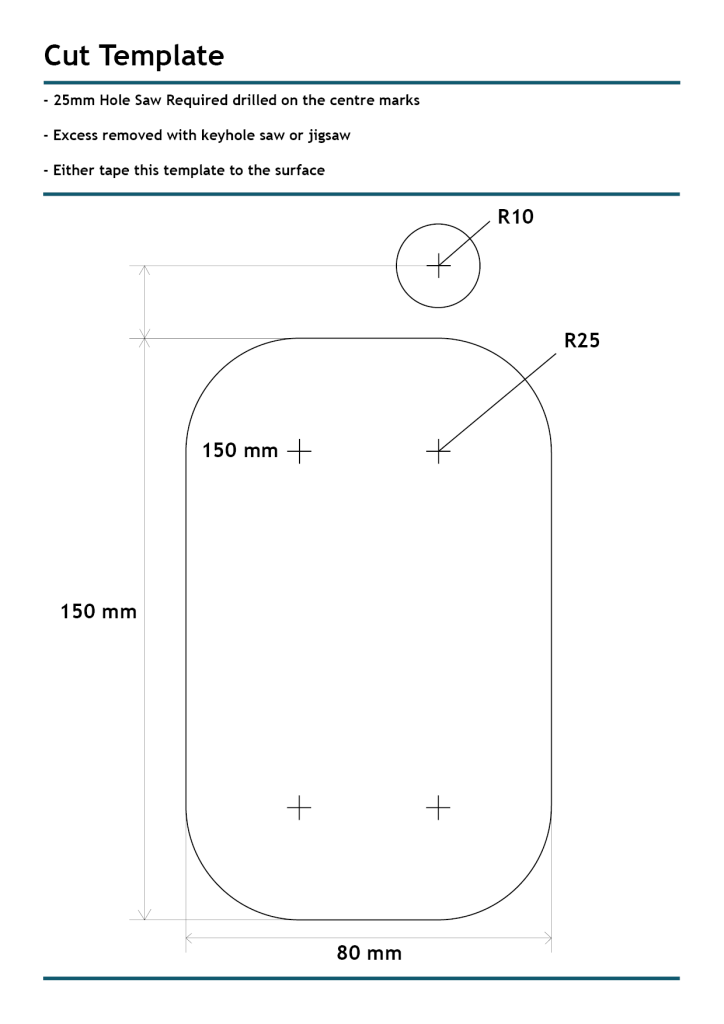

These are placeholder images hower the pdf can be downloaded and the link can be clicker to go to the correct parts.

Circuit Manufacture

The Idea would to be have a centralised hub which accepts pre made circuit board. These would either be milled or acid etched. A formalca coating would be applied to keep the moisture away from the electronic and waterproof.

A pick and place machine, and then an oven would be used to solder the board together. The pick and place machine works for surface mount components well and precisely places components where they are required.

Impact

Overall Supply Chain for the Milk Keg Delivery System

Gastronorm

As many of the components within the design are standards starting with the gastronorms. The chosen gastronorms are made from recycled HDPE in Germany [a.i]. The design will fit any brand of gastronorms as they conform to a standard. They are also made from the same material as milk bottles. I would be turning the milk bottles into a more sustainable case, which then reduces the demand for new milk bottles. Milk bottles are easily recyclable so if a cafe wanted to keep a weeks worth of HDPE bottles, they could in theory send these off to have a device made, or could produce their own casing from their last batch of milk bottles, before switching to the keg system.

Copper components

British made copper pipes and fittings are made [a.ii] and would be encouraged to be used by myself to customers. Because those are also available locally from plumbing stores and the likes of B&Q, it does mean they would be transported in bulk and then distributed locally. They are also made from a fully recyclable material and the fittings can be reused, omitting the crush olive used for the compression fittings.

All electronic components would be sold as a kit and delivered as one package to the user. The 3D printed casing could be made locally by maker spaces or a FabLab. Alternatively it could be distributed with the electronics kit from a central hub. The 3D printed parts would be made from PETG which is recyclable and chemical resistant. Its hardwaring properties would mean that it would last for a long period of time before being replaced, mostly likely lasting indefintely. The silicone or pcv pipes would have to be replaced long before the casing.

Device delivery system

HDPE bottle replacement

I will focus on the analysis for the plastic bottles being replaced by the metal kegs. The social impact and physical impact are both important to a successful and effectual product.

If the keg system could not be implemented, then this project would still have a strong argument to be used within a cafe, especially following COVID-19.

Reduction in plastic waste –

- If dairy taken up then plastic gone completely

- If LAC used but not delivery kegs – 6 pints replace 4 pints therefore reduction in plastic waste by 20%. This equates to a 40kg reduction in plastic for Parade & Albany in just one year.

Hygiene

- Copper is antibacterial

- reduces touching of dirty bottles then touching cups etc

- reduces milk waste by getting rid of

Security

- Allows businnes to reopen safely and reduce contact

- Allows customers to feel safer and that their is less contact with the dirty side of the deliveries

LAC prevents a constant influx of 4 pint HDPE bottle into cafes and replaces them with either reusable metal kegs or 6 pint milk bottles. Simply using 6 pint bottles would use 1/5th less plastic, equating to 40 less kg for an average size small cafe every year.

Reduced startup cost compared to the various options avalible, allowing more more cafes to use the system and less waste to be produced.

- The product prevents constant recycling and use of new HDPE milk bottles.

- The PETG material used can be recycled and turned into more filament and printed again. While this means it does have a further energy involvement, it does reduce the material waste.

- The copper pipe is also using competely reusable and recyclable materials

- The electronics are also standardised components and readily avaliable

- LAC has the ability to transform the small cafe environemnt, improving the working environemnt for both staff and customers. It reduced strain on staff, but make them bend overless to undercounter fridges, as well as reducing wrist strain if using 6 pint bottles.

- The cheaper alternative to competant milk systems, fills the gap in the market for small cafes, allowing them to improve hygiene standards. Very seldom will bottle be sanitized before being brought into fridges.

- Both feedback from baristas and potential customers have shown that even from an early stage in the project, ontap milk is a time saving and beneficial addition to any cafe.

- The adaptability of the design allows for many existing parts to be used and integrating local makers improves both the attachment and longevity of the design.